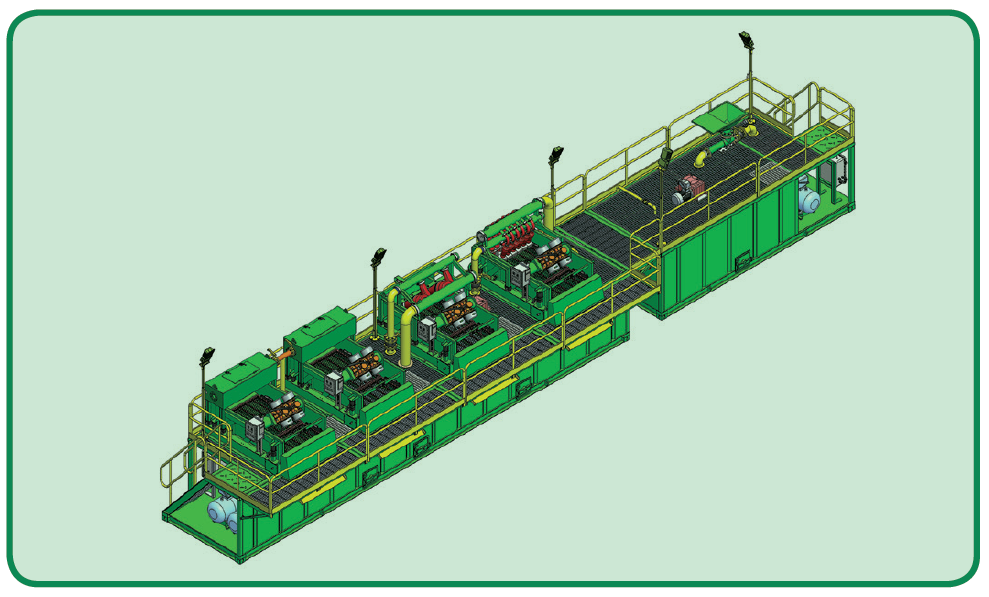

In recent years, GN Solids Control has developed construction waste mud treatment equipment for construction waste mud generated from subways, tunnels, bridges, and slotted continuous walls. The main equipments include centrifugal separation device and chemical treatment device, which can realize automatic operation, energy saving, emission reduction, high efficiency and environmental protection. It solves the construction environmental problems for the majority of users and reduces the construction difficulty.

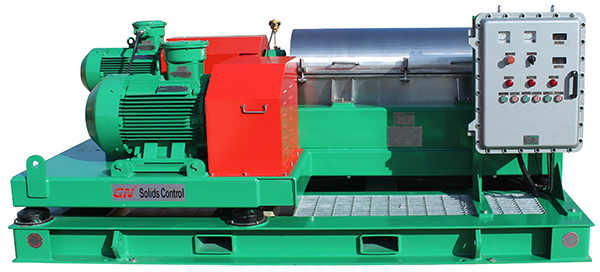

Introduction to automatic control of mud centrifuge separation system:

1, speed, differential speed, differential speed detection

Drum speed, auxiliary machine speed, differential speed are monitored by PLC in real time and displayed in real time on HMI; differential speed = (drum speed – auxiliary motor input speed) / differential differential ratio.

- After each run is completed, the automatic cleaning line needs to be run.

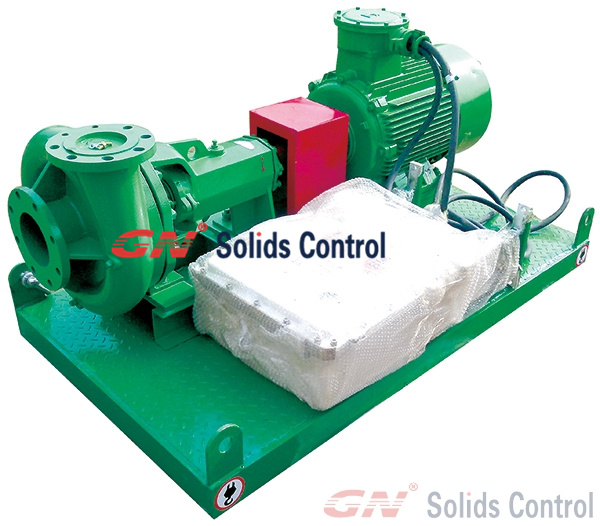

The selection buttons “stop flushing” and “stop no flushing” are set on the HMI. The user can select according to the actual situation; the shutdown flushing process is: after stopping the liquid supply pump 30S, the flushing valve (electric) is turned on, and the flushing valve is closed after 10 minutes. (Electric), then stop the main motor for 20 seconds and stop the auxiliary motor after 30 seconds.

3, vibration monitoring

A vibration switch is installed on the centrifuge body. When the vibration is greater than 7.1 mm/s, the vibration protection is activated when the vibration is greater than 10 mm/sec.

4, spindle bearing temperature

The main bearing at both ends of the drum is equipped with a thermocouple to measure the temperature, the temperature reaches 85 degrees alarm, and 95 starts the shutdown protection program.

We will talk rest info in next page,to be continue……

More question,welcome contact GN solids control