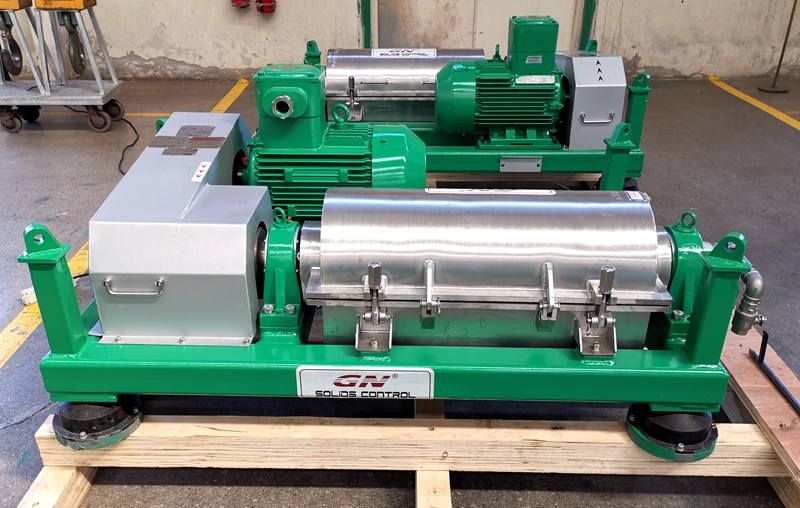

Recently, three set GNLW364EP-VFD series decanter centrifuges, one GNLW224EP-VFD series decanter centrifuge and one GNZS752F series drilling fluid vibrating screen produced by GN Solids Control have been commissioned and ready to be sent to Russia. This customer has been cooperating with our company for many years. The GN Solids Control brand equipment has the characteristics of stable operation, good processing effect and relatively favorable price, and has reached a strategic cooperation agreement. In addition, our company has reached a strategic cooperation agreement with AKROS, Russia’s largest mud service company, and became a supplier of Gazprom (abbreviated as Gazprom), supplying solid control equipment all year round.

The centrifuge is mainly used for oil drilling mud separation and processing, drilling waste treatment industry, and related equipment also includes and is not limited to: shale shaker / vertical cutting dryer / pumps / agitators

This project’s GN Solids Control GNLW364EP -VFD series decanter centrifuge is designed for a single processing capacity of 35m3 / h, and its design maximum speed is 3900RPM. Using frequency conversion control, the conventional speed is adjustable between 0-3200RPM. The maximum separation factor is 3063G, and the diameter of the separated particles is 2-5μm. The differential torque is 3500N.M and the main motor power is 37KW.

The following are the characteristics of GN Solids Control 364EP series decanter centrifuge:

1. The drum is made of duplex stainless steel SS2305 by centrifugal casting, and its performance is better than that of peer SS304 and SS306.

2. The centrifugal casting process makes the drum texture more uniform and has good dynamic balance performance.

3. The slag discharge port of the centrifuge and the discharge port of the screw pusher are all set with tungsten carbide cemented carbide sleeves, which have extremely high wear resistance and are not easily broken.

4. The screw pusher is embedded with wear-resistant alloy sheet, which has a longer life and reduces the number of maintenance.

5. PLC control panel control, the sensor can be installed on the centrifuge to monitor the state of the machine.

The centrifuges produced by GN Solids Control are widely used in drilling mud treatment, sewage environmental protection treatment, oily sludge treatment, solid-liquid separation in the chemical and food and beverage industries.

If you are interested about this news, welcome contact GN Solids Control to get more detail